Products

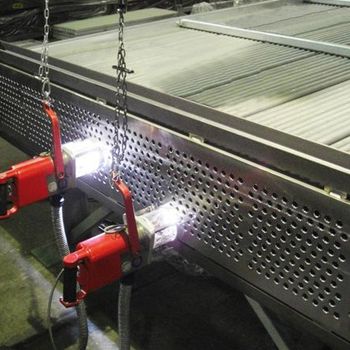

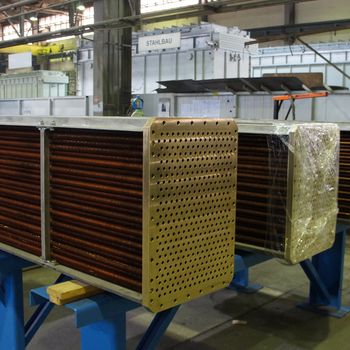

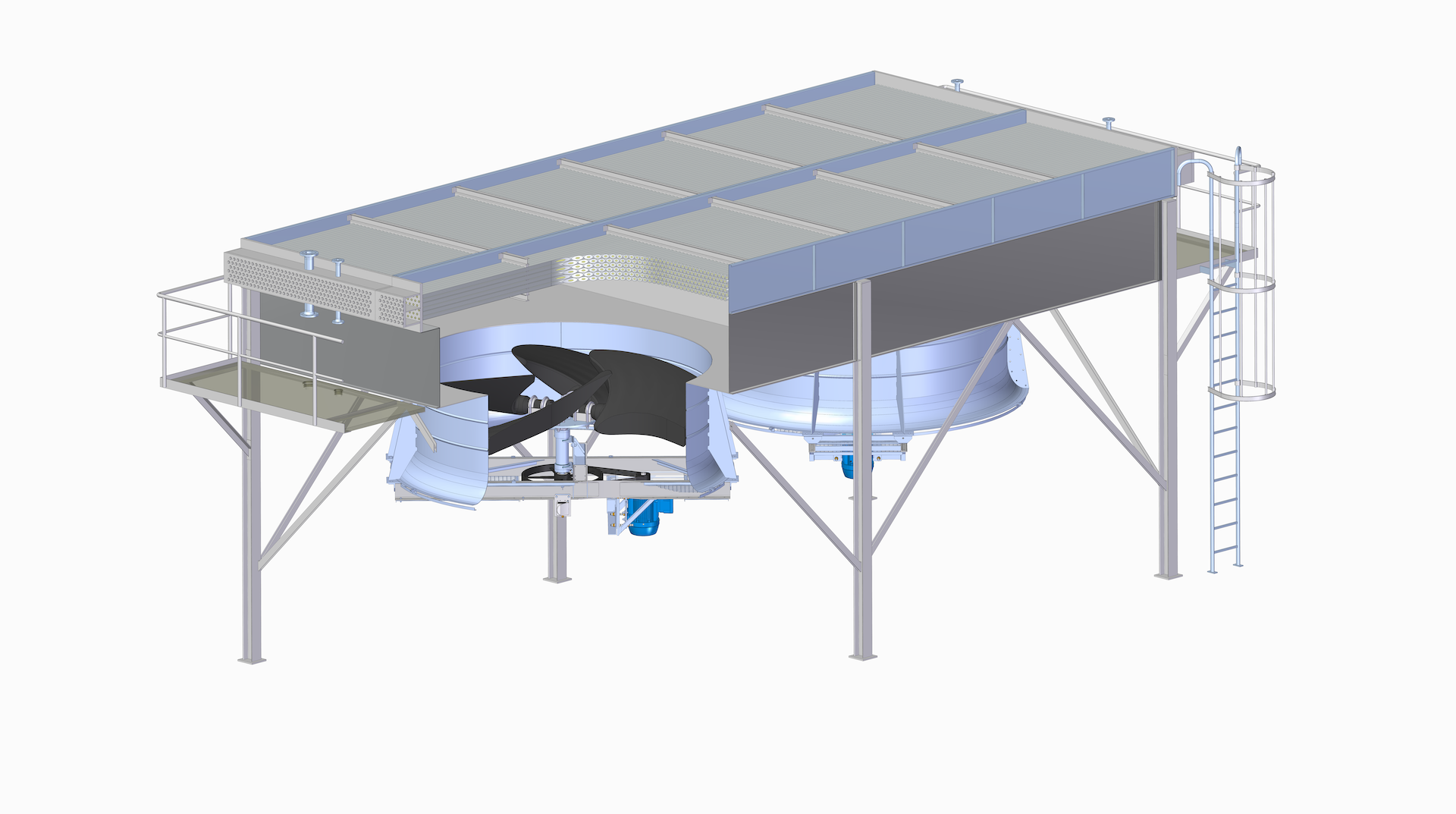

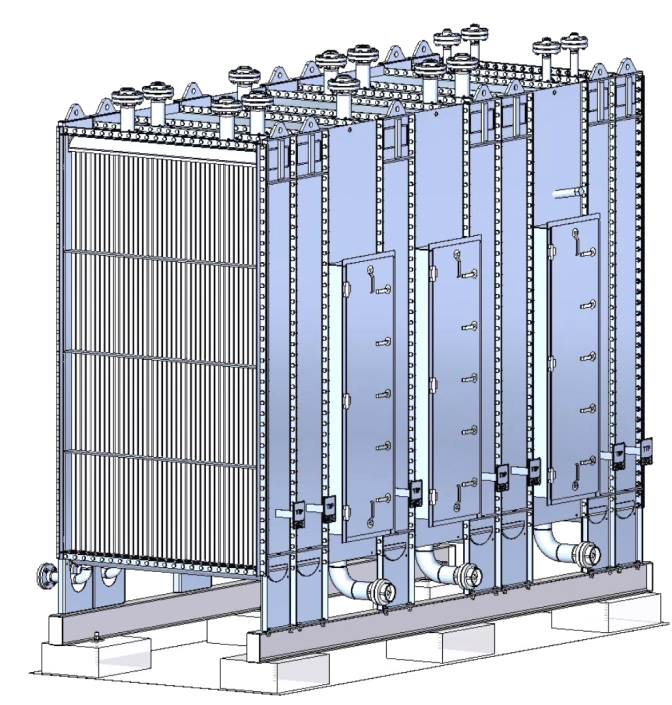

TUBETECH GmbH offers extensive expertise on air cooled heat exchangers and combines project planning and production under one roof at our facility in Plauen, Germany.

Design parameters

|

|

heat exchanger weight: up to 30t |

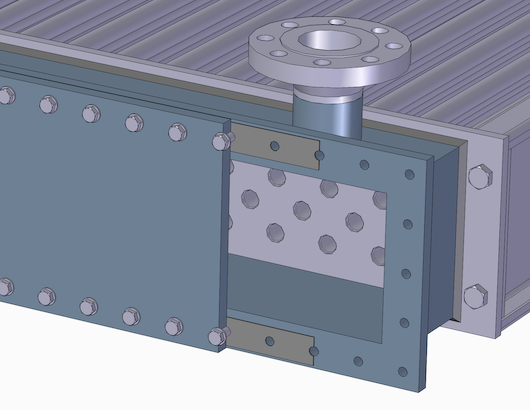

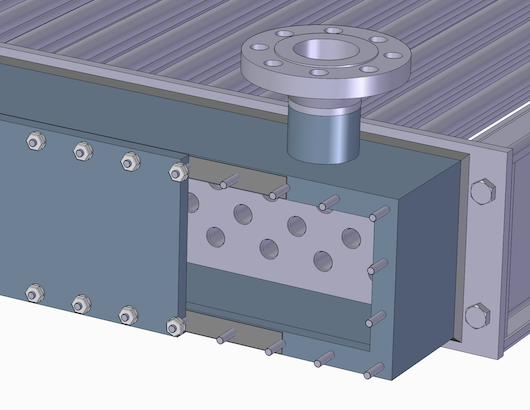

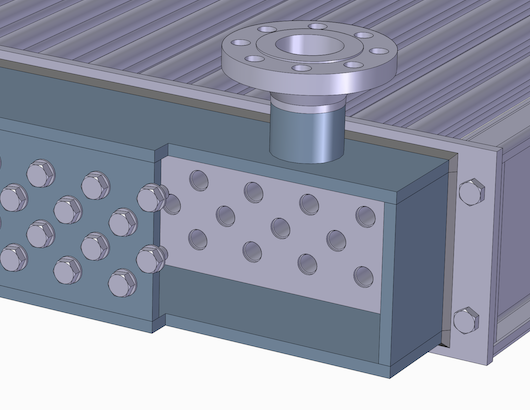

Header design:

| Bonnet header (welded D Type) | Removable cover-plate header | Plug header |

|---|---|---|

|

|

|

|

Design range: standard: up to 25 bar, costumized design possible up to 100 bar |

Design range: up to 40 bar, customized design possible with higher pressure |

Design range: up to 250 bar |

Design parameters

|

|

heat exchanger weight: up to 30t |

Header design:

| Bonnet header (welded D Type) |

|---|

|

|

| Design range: standard: up to 25 bar, costumized design possible up to 100 bar |

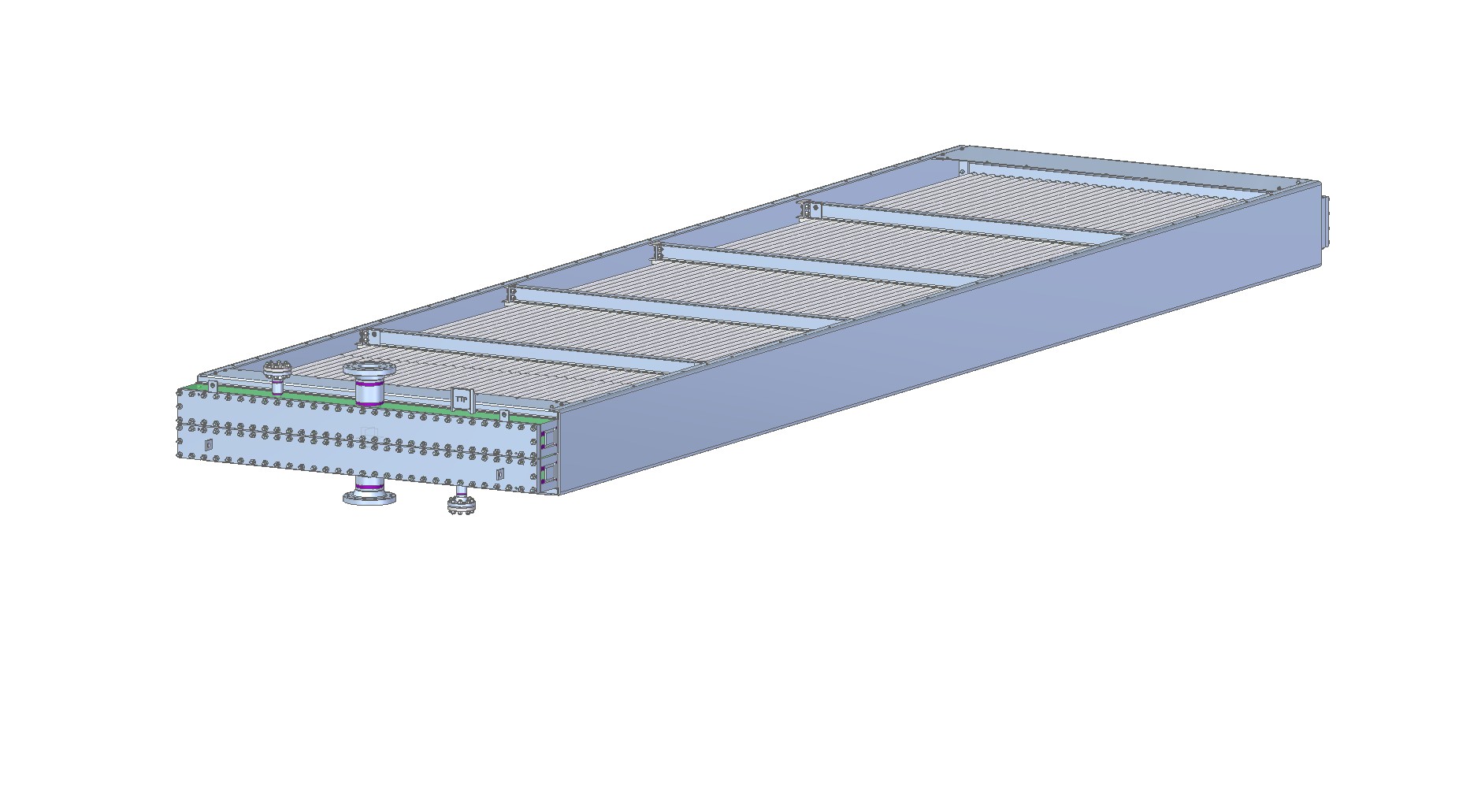

Design parameters

|

|

heat exchanger weight: up to 30t |

Header design:

| Bonnet header (welded D Type) | Removable cover-plate header | Plug header |

|---|---|---|

|

|

|

|

design range: standard: up to 25 bar, costumized design possible up to 100 bar |

design range: up to 40 bar, customized design possible with higher pressure |

Design range: up to 250 bar |

Parameters

|

|

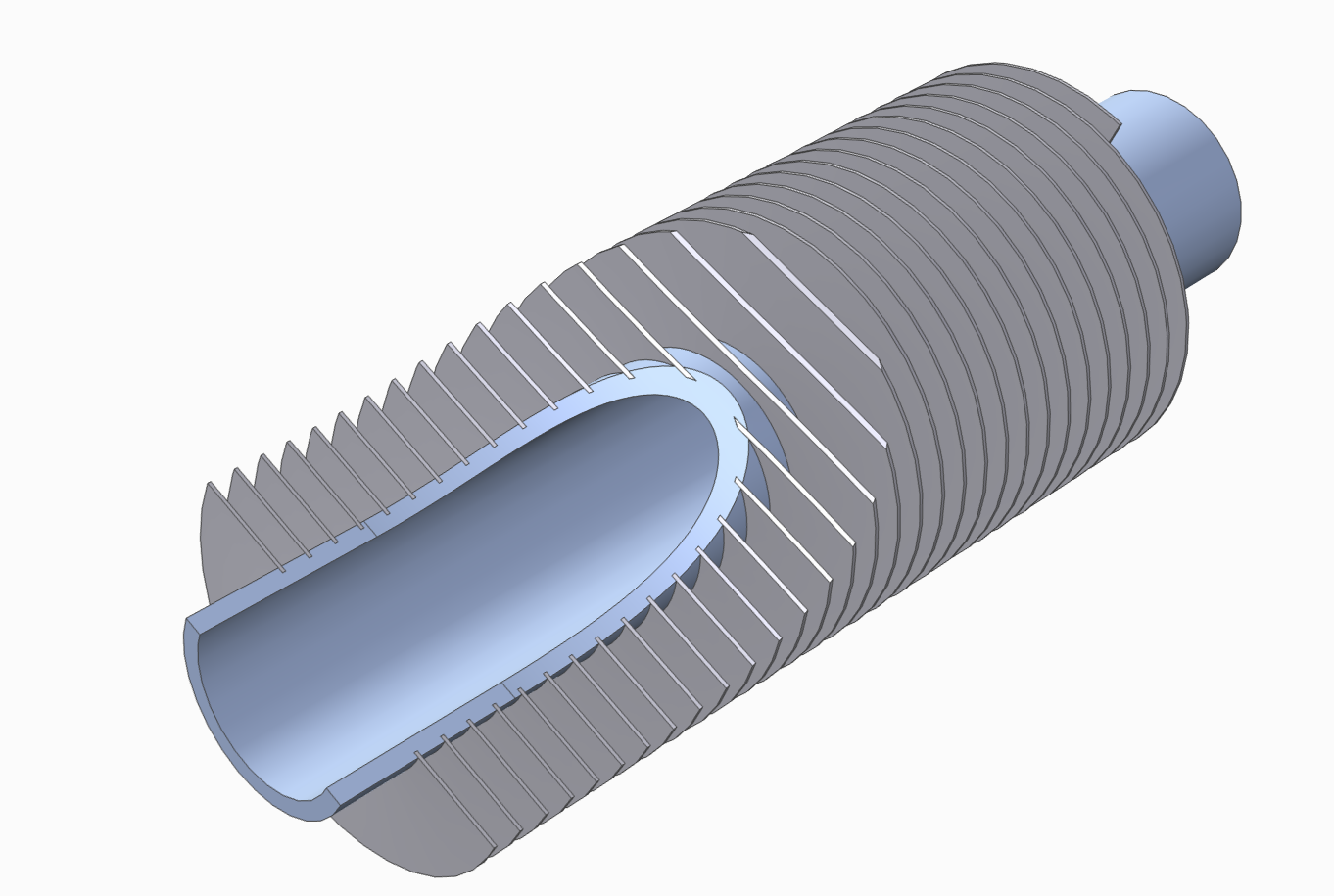

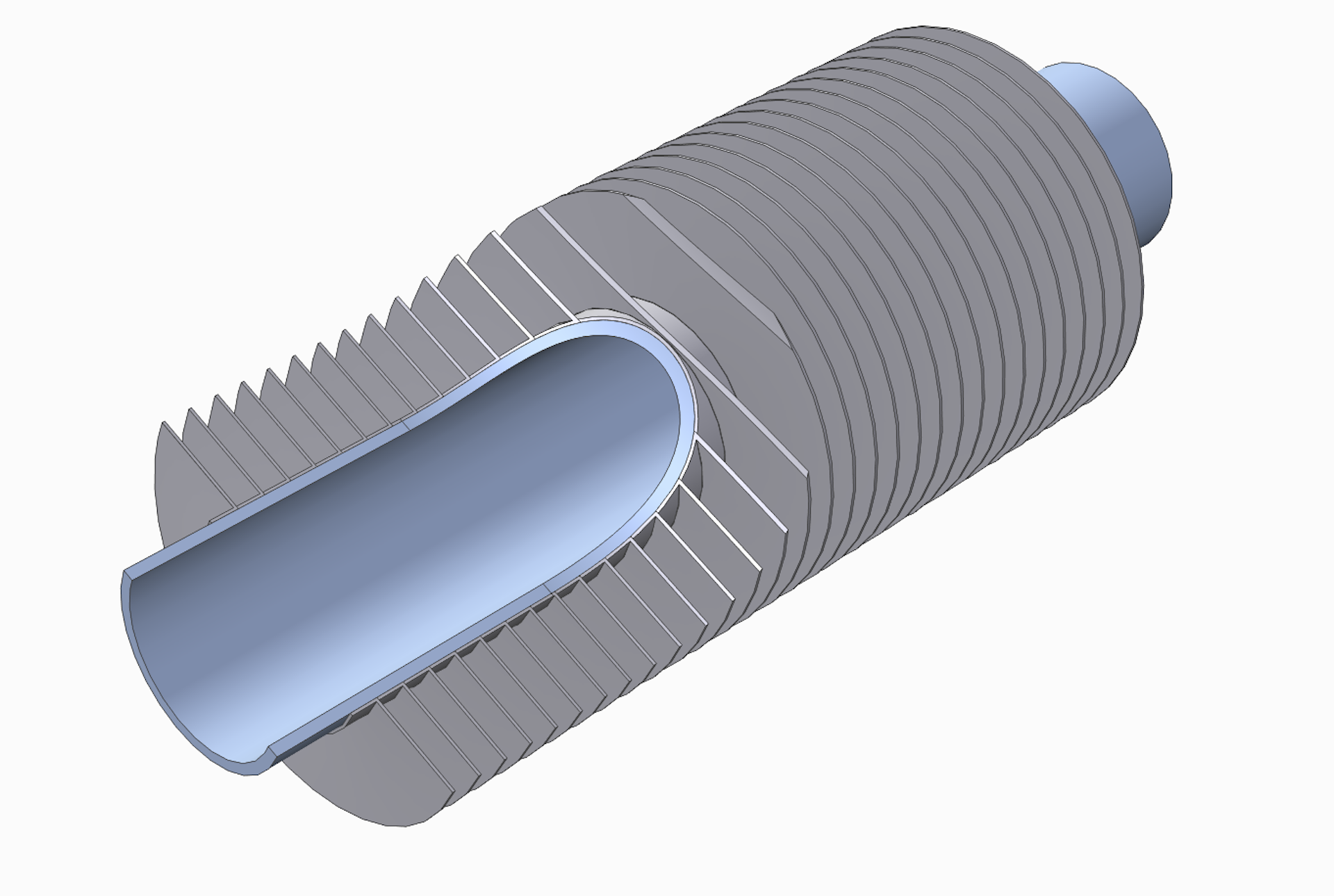

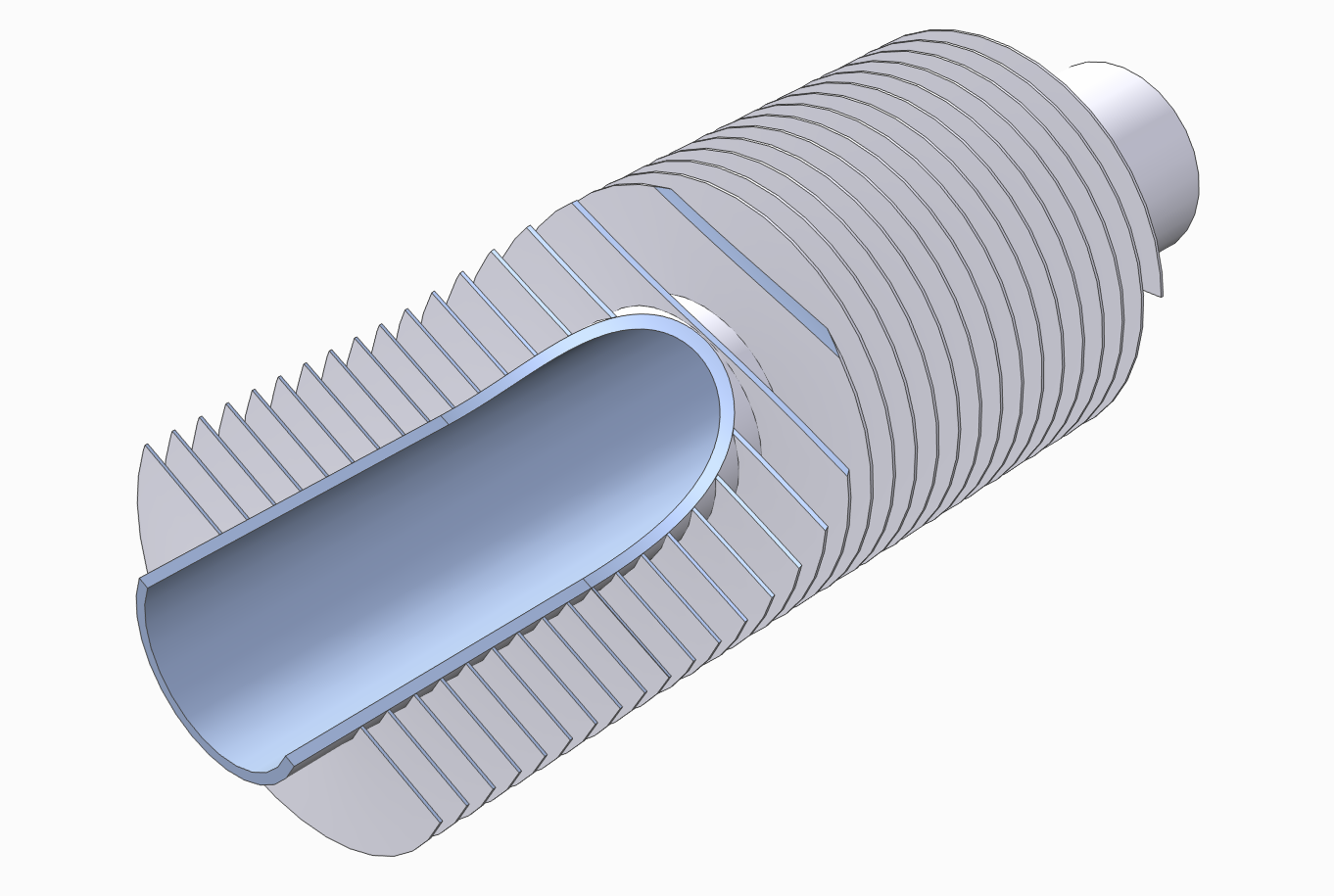

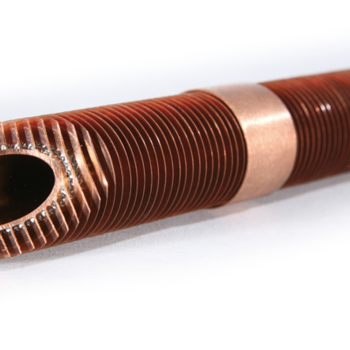

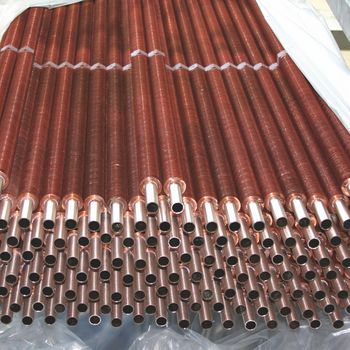

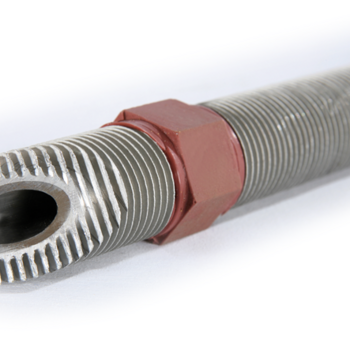

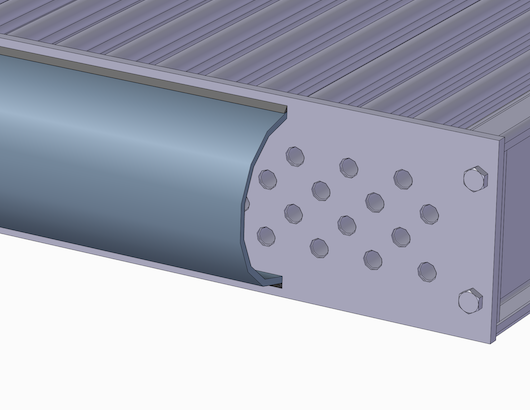

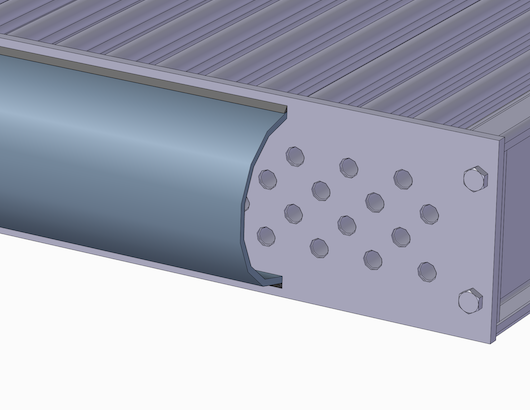

Outside diameter core tube (d): Ø 15 – 51 mm |

High fin tubing geometries:

|

Bi-Metallic (E-Fin / extruded) |

G-Fin |

|---|---|

|

|

|

|

L-Fin, KL-Fin (also tinned) |

I-Fin (galvanised, also tinned) |

|---|---|

|

|

|

Materials

|

Core tube |

Fins |

|---|---|

|

|

Parameters

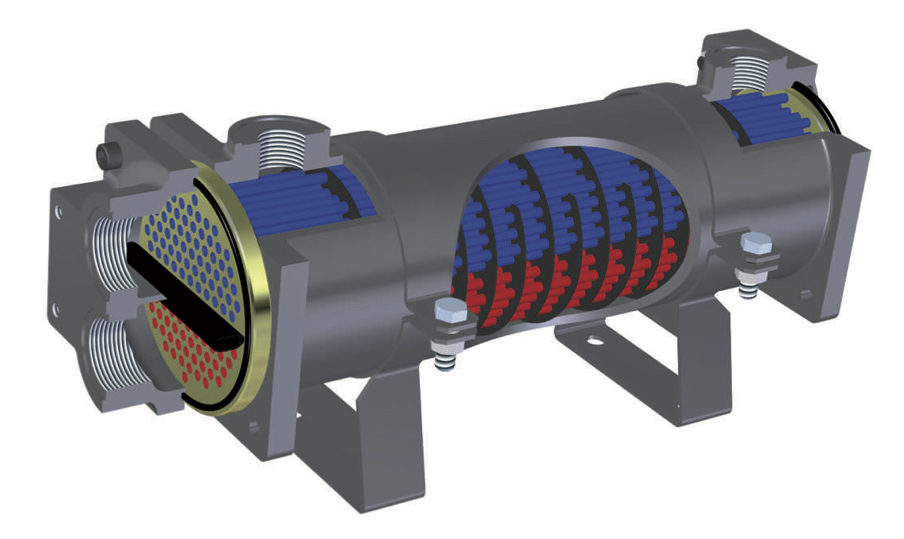

Tubetech high-duty coolers are tubular heat exchanger for heat duties as an oil cooler from 2 - 80kW and as a water cooler from 8-320kW. Of course, the heat flow can also be reversed so the cooler becomes a preheater. Other fluids are possible as well. The heat exchangers are manufactured according to the Tubetech works standards, which follow national and international standards in terms of design and strenght.

The advantage of the Tubetech high duty cooler is the small footprint and the variety of connection options. Vertical and horizontal arrangements are possible. With the clamp feet the heat exchangers can be rotated in horizontal arrangement and the distance between the foots can be set variable. All these features are possible thanks to the exact manufacturing tolerances and standardization.

TubeTech High-Duty Coolers are designed for the following conditions:

Shell side:

- Design pressure: 20 bar

- Design temp.: 120°C

Tube side:

- Design pressure: 20 bar

- Design temp.: 120°C

Material:

- Shell: CAlSi5Mg

- Headers: CuSn5ZnPb

- Tubes: CuNi30Fe

- Tube sheets: CuZn38SnAl

- Baffles: St37-2

- Gasket: Perbunan

- Bolts: 8.8

We will be glad to advise you

Address

TUBETECH GmbH

Hammerplatz 9

08529 Plauen

Germany

Phone: +49 (0) 3741 280 60

Fax: +49 (0) 3741 280 640

E-Mail: info@tubetech.de