At a glance

process design via different calculation programs

- HTRI

- Lauterbach Verfahrenstechnik

- In-house developed software, based on measurements

Engineering, constructional design

- 2-D, resp. 3-D design engineering

- Engineering of electrical ventilators, motors and other components

- Stress calculation acc. to AD-2000, EN 13445, ASME Code

- Preparation of general layout drawings and shop drawings

- Preparation of welding book and inspection and test plan

- Static calculation of supporting structure

Project Management

- Preparation of production flow plan via MS-Project

- Proactive forwarding of monthly progress reports with pictures of current status of manufacturing

- Weekly project meetings in order to safe contractualdelivery dates and quality standards

Manufacturing, Testing

- Acc. to requirements of national and international regulations (e.g. AD 2000, EN 13445, ASME) and specific customized regulations

- Quality inspection / - monitoring

Delivery of components and accessories

- Supporting steel structure, platform, ladder

- Fan rings, incl. drives (direct drive, V belt drive, gearboxes)

- Fan and motor

- Louver

- Vibration switch

- frequency converter

- switchboard/cabinets

- external noise protection

Assembly and service

- international experienced, in-house service team with longterm experience in assembling, service and repairing of products, inside and outside of OELTECHNIK group

- more information: oeltechnik-service.com

Quality management

In the wake of worldwide globalization, an ever increasing importance has been attached to quality management at TUBETECH GmbH in recent years, too. Standardized costs and customer-oriented products of highest quality are in demand more than ever before.

This trend has been understood at TUBETECH GmbH at an early stage. Thus, the quality management system certified according to DIN ISO 9001:2008 is geared to define all and any internal processes with a direct or indirect impact on the manufacture of products to mach all customer requirements in an efficient manner.

Control processes starting from incoming goods inspections to worker self-monitoring until final inspections are performed using sophisticated technology and are integrated in the production run. Intensive qualification of workers and comprehensive training of in-house quality and inspection personnel, support and enhance the quality of products produced at TubeTech GmbH.

Test methods or inspection procedures used, such as

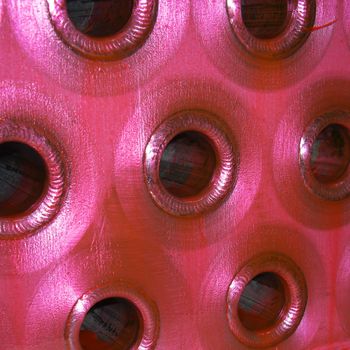

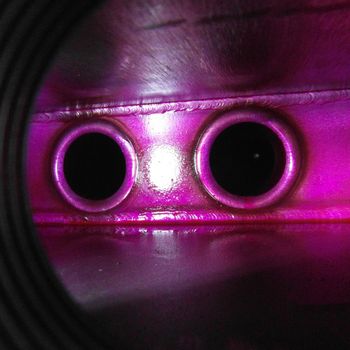

- dye penetrant testing,

- visual inspection,

- magnetic particle inspection,

- ultrasonic inspection and

- (external) radiographic inspection

can be implemented in coordination with the production department, or jointly with the customer.

Customer satisfaction is further enhanced through comprehensive and detailed documentation that can be traceable at any time and is taken for granted within our organization.

Due to this high standard of quality management, our organization is certified according to DIN ISO 9001:2000 and the manufacturing standards DIN EN, PED 97/23/EC and ASME VIII/1 U-stamp.

Ongoing improvement is a premise of our corporate management. In conjunction with ENVIRONMENT and QUALITY, this is a serious concern with a view to achieve customer satisfaction through quality products “Made in Germany”.